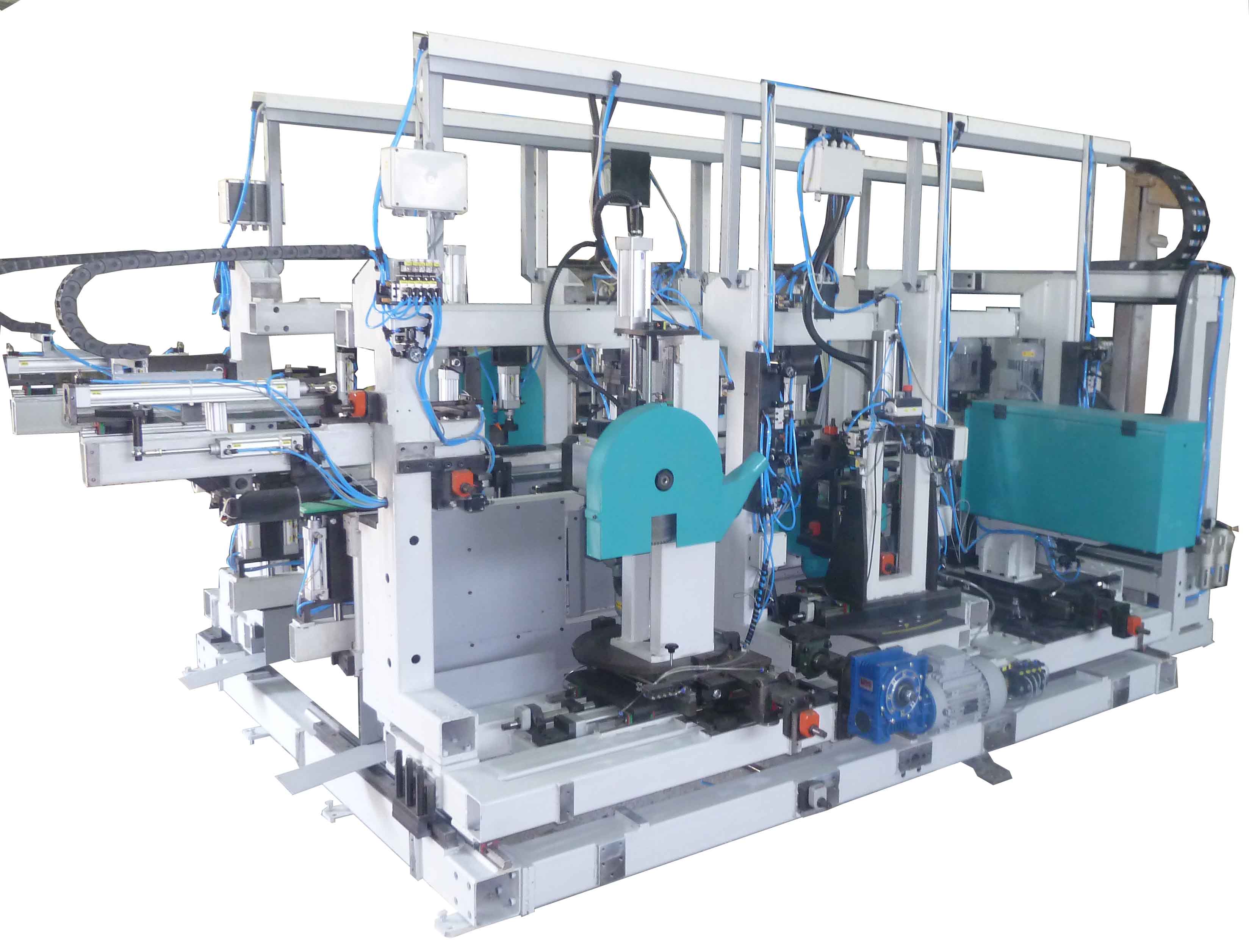

Automatic Combined machine COMBY

The automatic combined machine is a multi operational machine designed for cutting, milling, sanding and drilling of chair legs and other details.

Configuration of the machine according to the kinematic plan:

1. Magazine for the details

2. Manipulator

3. Combined circular saw cutting and copy milling aggregate

4. Circular saw cutting aggregate

5. Chamfering aggregate - 2 pieces

6. Belt sanding copy aggregate

7. Top drilling aggregates – 2 pieces

8. Bottom drilling aggregates – 2 pieces

Technical data

| Maximum width of the detailsлите | 60мм |

| Maximum thickness of the details | 60мм |

| Maximum length of the details | 1100мм |

| Minimum length of the details | 420мм |

| Manually feeding of the magazine | |

| Manually taking out from the end of the machine | |

| NC programmable manipulator | |

| The motors of the circular saw aggregates are frequency controlled | |

| The motor of the copy milling aggregate is frequency controlled | |

| The motors of the chamfering aggregates are frequency controlled | |

| The motors of the drilling aggregates are frequency controlled | |

| Up to 60 mm oscillation of the sanding belts for the stations (6). The frequency of the oscillation is adjustable. |

|

| Digital (mechanical counters) indication for set up of the working stations. |

|

| The machine is controlled with PLS programmable controller with display for entering the necessary data | |

| Productivity | from 6 to 10 pcs./min. |

| Instigated power | 30 kW |

| Compress air needed | from 4,5 to 6 At |

| Extraction air | 12 000m3 /h, Speed – 28m/sec. |